Boss Laser Not Cutting Through

These can range from the settings you have selected in the software to the type or appropriateness of your material.

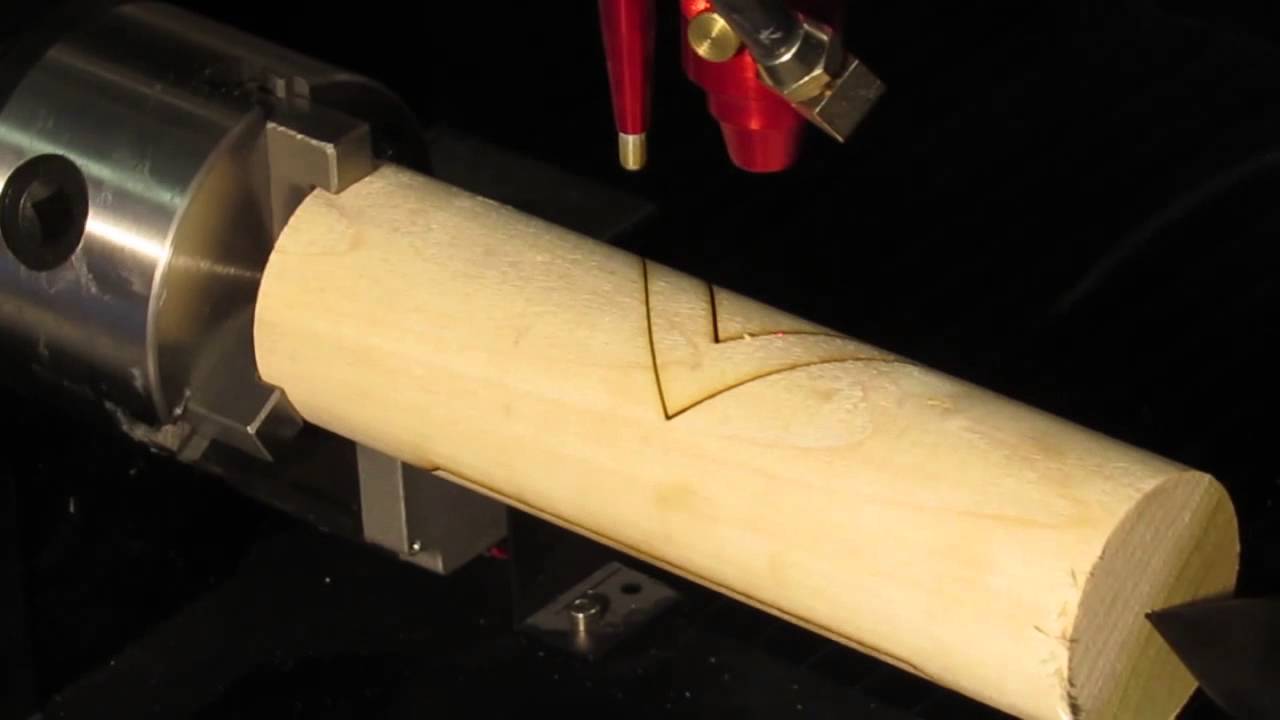

Boss laser not cutting through. The co2 laser wavelength is not efficient at metal cutting which is why we offer a line of fiber laser cutting and marking machines. After the laser does the engraving it will come back and burn a thin line around the very edge. Images are used as visual to show types of materials that a co 2 laser can enrgave etch or cut. I have another laser engraver but was never trained on how to use it and have self learned all these years what josh taught me in spending day with me i only wish i would have met him years earlier.

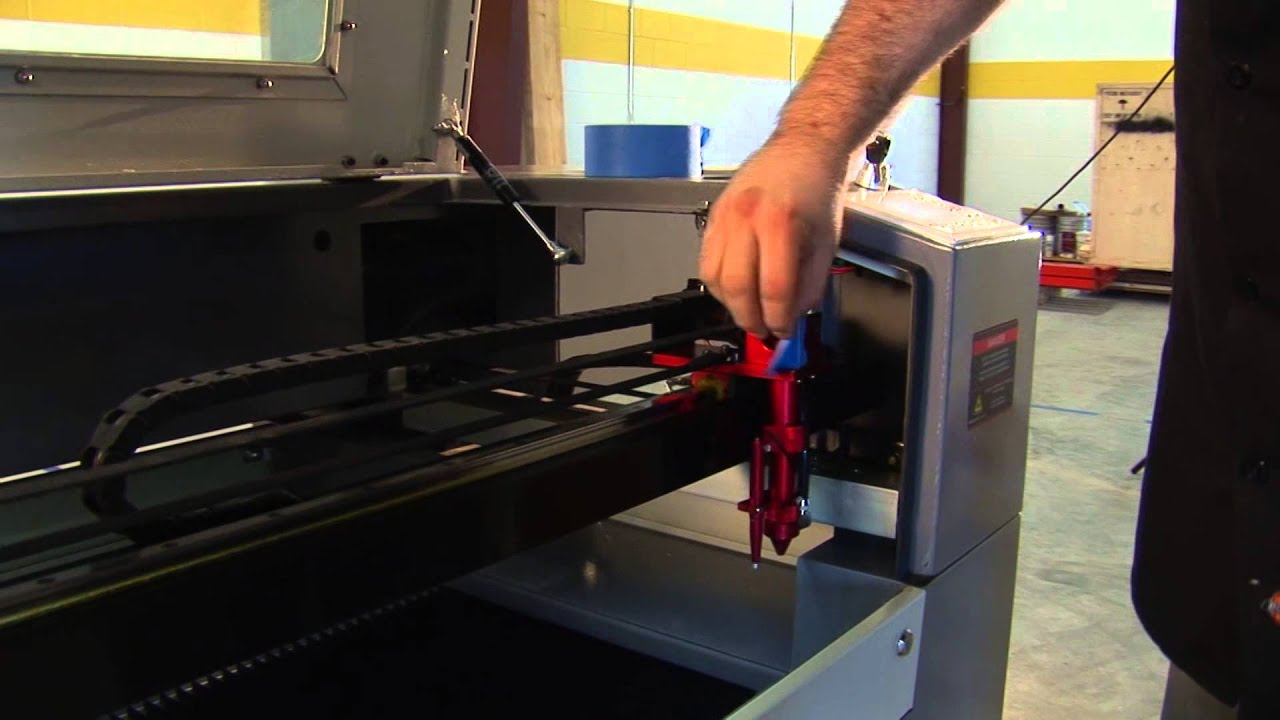

The air filter coolant and air pressure must be on during laser cutting. There are a whole host of materials that a co2 laser cutter can cut etch or mark but some due to the material surface reflection just won t work aluminum is an example. Laser troubleshooting guides the pdf trouble shooting guides represent some of the more common questions or issues that you may encounter with a boss laser cutter. How thick of wood can a co 2 laser cut through.

The laser is not cutting through my material. I thought i had my machines focused and running close to perfect not once he refocused and did adjustments this boss laser is the boss. The pdfs are laid out in a step by step fashion with supplementary links to relevant boss youtube videos. Do not clamp the workpiece on this machine during laser cutting and engraving.

Images may or may not be actual materials processed by boss laser. The co2 wavelength makes our industrial co2 laser cutters ideally suited for all types of organic materials such as wood acrylic leather plastics fabrics etc. When you set up the laser set the stroke for a vector cut but turn the power down and increase the speed so it burns but doesn t cut through the edge. You first need to understand how the lens works.

There are many settings and conditions that can affect the laser s interaction with your work piece. Clean this tray after use. Factors such as the speed of the laser and the type of wood being processed will alter a. Multiple factors are at work here but generally speaking a co 2 laser with 50 watts of power is more than capable of cleanly laser cutting thru 1 4 wood in a single pass and up to 3 4 with 150 watts.

The laser is not cutting through my material. Never cut aluminum copper titanium plate and galvanized steel sheet. May 31 2018 20 13. People often ask me why the edges of their laser cuts are not square.

All of the images are exaggerated to show the affects. You can also receive laser cut acrylic samples if you re interested in seeing a boss laser finished design.