Boss Laser Z Axis Not Working

If you should call after hours or during a holiday or weekend you can email or leave us a voicemail and we lll get back with you typically within a few.

Boss laser z axis not working. Boss laser machines include laserworks v8 a stand alone software interface that enables intuitive design work that many of our clients prefer to use over other commercial software. If the problem persists then we must turn our attention to the table wiring. Laser troubleshooting guides the pdf trouble shooting guides represent some of the more common questions or issues that you may encounter with a boss laser cutter. The pdfs are laid out in a step by step fashion with supplementary links to relevant boss youtube videos.

Always turn the exhaust fan on while running the laser. Going over auto focus use with boss laser and rdworks. Insure that the spindle is square in the mount or block. Boss laser support should you have questions or need help with understanding or trouble shooting your new boss laser cutter or laser accessory our technical support department is here to help.

Fiber laser marking machine with auto z axis to mark on products with different height. Always use protective eyewear preferably wraparound goggles. Never operate laser machinery unless you have been properly trained. Never set anything on top of the laser.

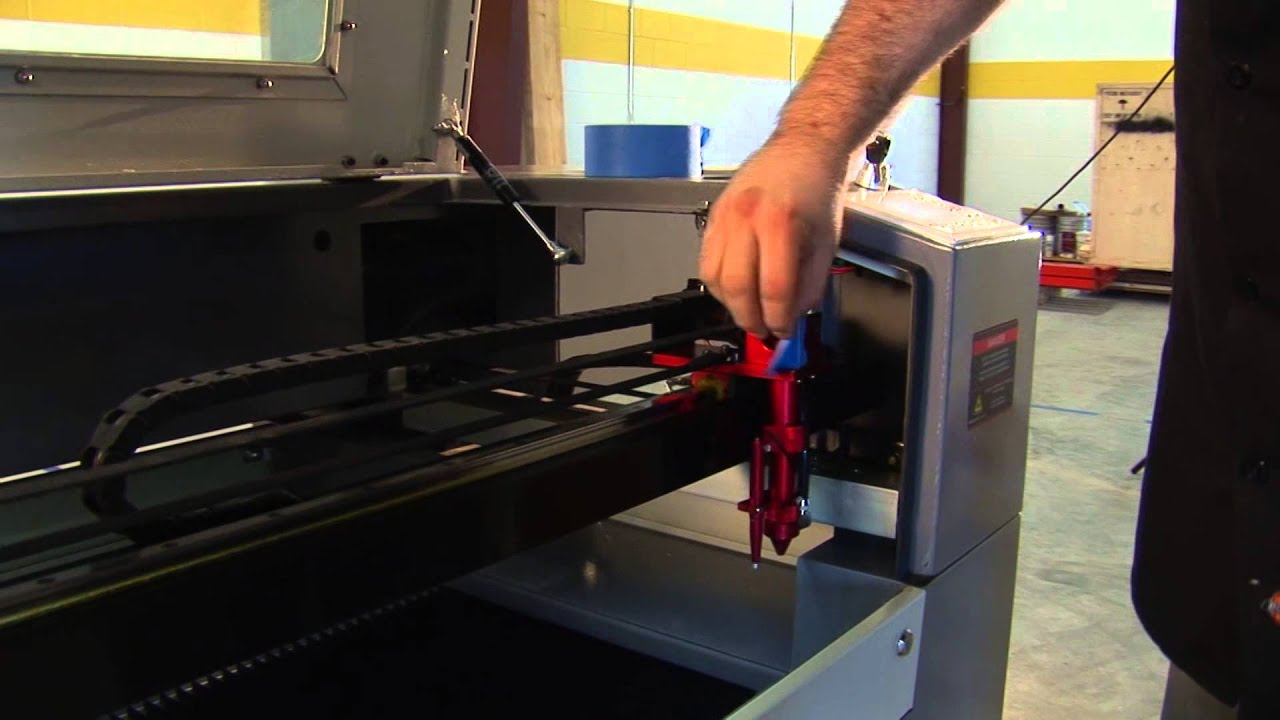

The first is to swap the z axis driver board. A spindle that is not square to the engraving surface means that the cutter will also not be square to the material surface. The document for doing this is listed below. Besides that all that is necessary is to adjust the laser power and speed settings to the material that you decide to use.

Never dismantle the laser machine. If you have a z axis that is grinding chattering or just not working at all here are the steps to follow to isolate you problem.